From Delay to Delivery: Reducing Lead Time with BOM Creator

Introduction

In

today’s fast-paced manufacturing, precision is essential. While traditional

BOMs list components thoroughly, they often lack operational clarity especially

for long lead items. The key question remains: What needs to happen first,

and why—particularly when long lead items are involved?

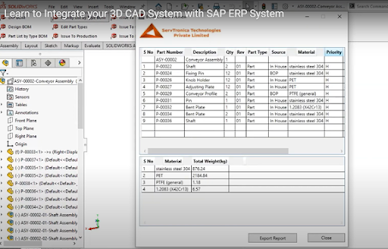

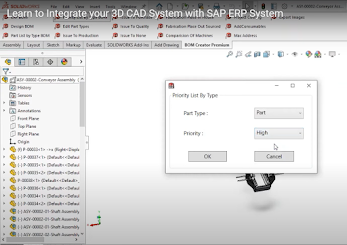

The Priority List by Type BOM

feature addresses this challenge by enabling structured visibility and

prioritization. It ensures teams identify and act early on critical or long

lead items, aligning sourcing and production with lead time realities and

keeping workflows on track.

Even with the best tools,

manufacturers face common hurdles leading to avoidable downtime, rushed

adjustments, and production inefficiencies.

“Without prioritization, a BOM is just a list. With it, it becomes a production roadmap.”

Feature Overview: What is Priority

List by Type BOM?

Servtronica’s solution takes BOM

management a step further by transforming a generic parts list into a strategic,

production-ready execution tool. This feature is especially valuable for

projects involving long lead items components with extended procurement

or production timelines. Early visibility ensures sourcing begins before delays

occur.

- Categorization

by Type: Group

parts under logical types such as Machining, Fabrication, Electricals,

BOP, and Hardware.

- Priority Tiers: Each item is assigned a priority tag High (🔴), Medium (🟡), or Low (🟢) based on production need.

- Dependency

Mapping: Identify

parts that impact downstream processes to prevent delays.

The visuals below highlight how

prioritization transforms BOM data into a clear production strategy, as illustrated

through real-world platforms like SolidWorks and Solid Edge. While BOM Creator

integrates seamlessly with tools such as Inventor and more, these examples

demonstrate how it transforms static BOMs into dynamic, priority-driven plans.

“SolidWorks reflects how components are grouped and prioritized bringing immediate clarity to production-critical parts.”

.png)

.png)

“Solid Edge enables BOM-level

sorting by type and urgency guiding teams to focus on what matters.”

.png)

From Insight to Execution: The

Value Delivered

This

feature enables faster, more coordinated execution by aligning priorities

across teams and timelines.

Regardless of the

platform—SolidWorks, Solid Edge, Inventor, or others the Priority List by Type

BOM feature introduces structure, speed, and synchronization, bridging the gap

between planning and execution.

“From visual clarity to operational

agility, it’s not just about managing parts it’s about moving forward with

purpose.”

Use Case in Action

Here’s how this feature translates

into real-world value on the production floor especially when managing long

lead items that must be sourced or fabricated well in advance.

A complex

project with over 300 components may follow this breakdown:

- 🔴 Machined Frames &

Structural Parts – Prioritized for immediate production kick-off

- 🟡 Motors, Sensors, and BOPs

– Scheduled for mid-phase sourcing and integration

- 🟢 Hardware and Finishing

Elements – Reserved for the final stage of assembly

This structure keeps long lead items visible,

prioritized, and accounted for minimizing production risk.

Plan

smarter. Prioritize earlier. Deliver on time.

BOM Creator- Re-Defining The Approach Towards The Bill Of Materials !!!

Shreya

Singh

📧

support@servtronica.com

📞

+91-9953432516 | +91-8595668427 | 0120-4265864

📍

Servtronica Technologies Pvt. Ltd.

Suite #818, Tower B, A-40, Block A, Industrial Area, Sector 62, Noida, Uttar

Pradesh 201301

.png)

.png)

.png)

.png)

Comments

Post a Comment